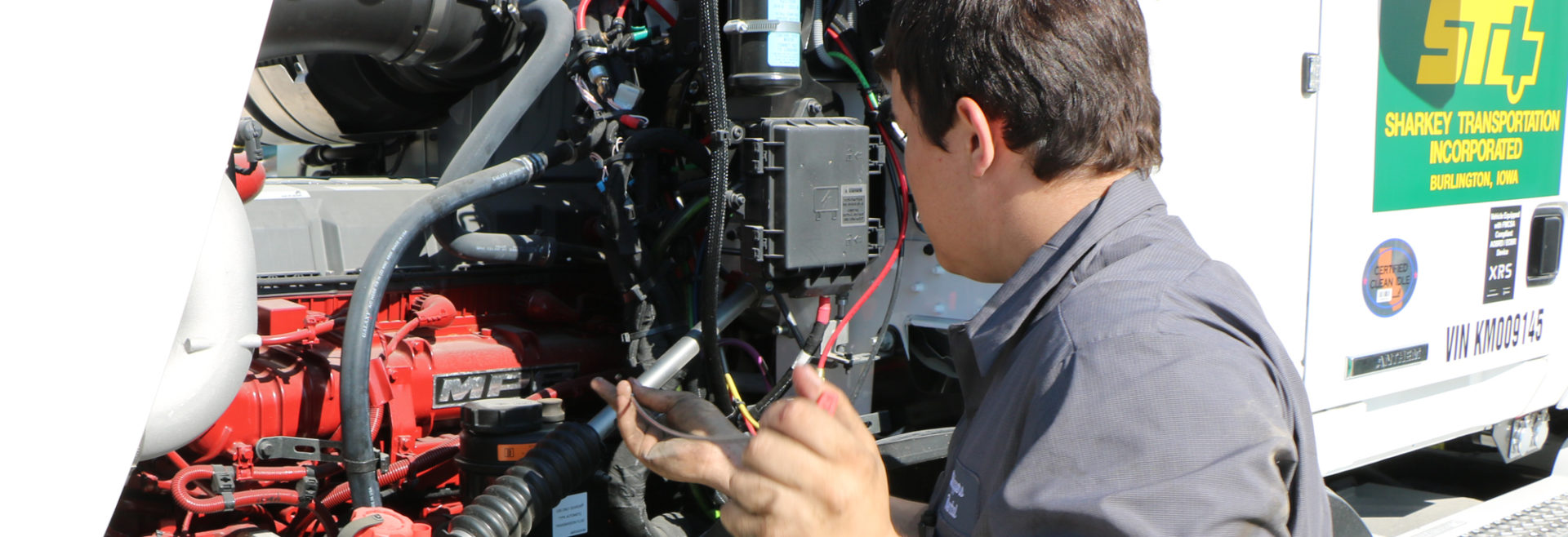

Diesel technician students learn to maintain, repair, and perform diagnostic testing for diesel powered transportation equipment used in multiple industries including agriculture, military, and construction. This eight-class certificate builds on the certified production technician certificate.

| First Semester | Details | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DET 101 | Diesel Technology I | Details | 8 | ||||||||

|

|||||||||||

| MAT 100 | Technical Mathematics | Details | 3 | ||||||||

|

|||||||||||

| MFG 113 | Introduction to Manufacturing & Industrial Safety | Details | 3 | ||||||||

|

|||||||||||

| WLD 101 | Maintenance and Repair Welding | Details | 3 | ||||||||

|

|||||||||||

| Second Semester | Details | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Various | CMN 101 / CMN 104 | Details | 3 | ||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| DET 102 | Diesel Technology II | Details | 8 | ||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| IMT 150 | Fluid Power I (Hydraulics) | Details | 3 | ||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| IMT 155 | Fluid Power II (Pneumatics) | Details | 2 | ||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

Gainful Employment: For more information about graduation rates, cost, the median debt of students who complete the program, and other information, please view our Gainful Employment information for the particular certificate of study.